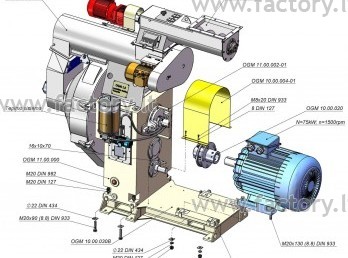

"Radviliskis Machine Factory" is producing pellet presses OGM-1,5 for more than 50 years. Together with that, we are producing most of the spare parts ourselves and always have them ready in stock for our customers.

Please download our catalogue, choose required spare part, and contact us for prices - [email protected]

Download PDF CATALOGUE here: OGM-1,5 spare part catalogue

The most important part in pellet press is ring die (matrix). According to the size of the ring die, channel diameter and length, pellets are made in different size and strength.

“Radviliskis machine factory” is selling original, highest quality German ring dies, additionally treated in our factory to reach highest possible quality and fit pellet press 100%. Ring die producer - “Graf”.

Specification:

- Diameter of ring die holes - from 1,8mm up to 14mm

- Channel length from 55mm up to 104mm

- Made of highest quality stainless steel

- Vacuum hardened

Ring die is composed of many vertically drilled holes. Depending on the selected materials, variable hole channel diameter and the length of the channel is chosen. Due to the high friction between the matrix and roller, heat is produced, which slightly (1-2%) lower raw material moisture.

The two main advantages of ring die pellet mill is reduced roller and die wear, and reduced energy consumption.

Production process:

Grinded materials are fed into the device and spreaders smooth the material into die and coat it. Two rollers compress the substance, pushing the material through the radial slots. Controllable blade hack the pellet according to a fixed length. Hot pellets are then carried in to refrigerator.

Together with the die - roller shells are equipped. Roller shells are made of stainless steel alloy. Vacuum hardened.

We offer the most suitable dies. Contact for more information and an exact price.

Dies, rollers shell and fully assembled rollers does not apply the guarantee.

Contact us and send the list of required parts for your pellet press.